Articles

The Almaden mines, an Andalusi heritage

Article author: Tristan Semiond

Date of publication of the article: 22/02/2022

Year of publication: 2022

Article theme: Al-Andalus, Archaeology, History, Science.

During the Al-Andalus period, mining activity was very important and the extracted materials were exported throughout the whole Mediterranean basin. One of the most important exploitations of the time was that of cinnabar, which was used for the production of mercury (ziʼbaq). The main mine for its extraction was located in the city of Almadén.

Cinnabar and mercury, when rarity makes prosperity

Mercury (commonly known as quicksilver) occurs in deposits mostly in the form of a mineral of the mercury sulfide class, the cinnabar. The earliest archaeological evidence of cinnabar use was found in Turkey (Çatalhöyük, 7000 BC, 8000 BC), Spain (Casa Montero mine and tombs of La Pijota and Montelirio, 5300 BC) and China (Yangshao 4000, 3500 BC).[1]

Due to limited cinnabar resources, mercury is a relatively rare metal. Despite this, its uses have long been irreplaceable in a variety of technical, chemical, medicinal and industrial processes. One of the main ones has been the pan amalgamation process[2] of gold and silver, a use that has made it a strategic product and a synonym of great wealth and power.

The entrails of Almadén, a secret quickly discovered

In this process of searching for cinnabar for the production of mercury, Almadén, a town in the Iberian Peninsula, stands out as containing one of the largest reserves in the world. Its discovery dates back to ancient times. Already in Roman times cinnabar was extracted and exported in large quantities to Rome, where it was used to manufacture vermilion, an intensely saturated orange-red pigment, which was employed in dyes, paints and cosmetics…

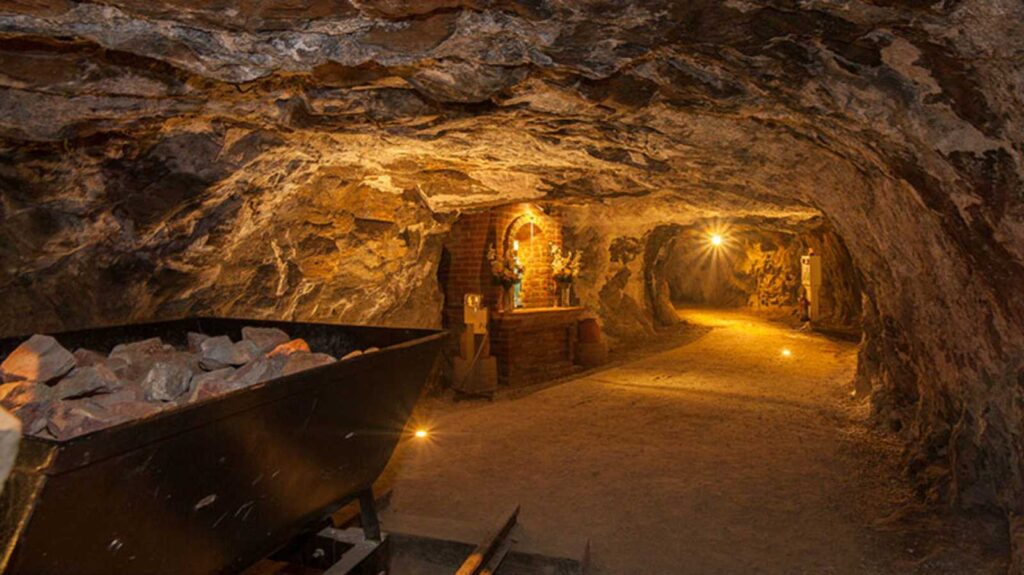

Due to this long history, the mining park of Almadén is considered one of the oldest in the world, since it was in operation about two thousand years ago until its closure in 2003. The role it played was so important that it is considered that one third of all the mercury used by humanity comes from the cinnabar extracted from this mine. This represents between 250,000 and 300,000 tons.

Therefore, when the Muslim troops arrived in the Peninsula and settled in the region of Almadén, the underground secrets of the area had already been discovered. However, a certain know-how typical of Al-Andalus was developed, as well as a whole economy around this activity.

The city of Almadén and its mines in the Al-Andalus period

The city of Almadén is located in the current Autonomous Community of Castilla-La Mancha, more specifically in the southwest of the province of Ciudad Real and at the westernmost end of the Alcudia Valley (whose name comes from Arabic and means “the mountain”).

The urban structure of the city is thought to be of Islamic origin, being composed of a series of buildings erected to defend the mine, called hisn al-ma’din, the “fort of the mine”. Thus, the name of the city also has an Arabic origin, deriving directly from المعدن (al-maʿdin), meaning “the mine”.

If the first period of exploitation, Roman and Visigothic, is poorly documented, the Islamic period – which lasted until 1151, when Alfonso VII conquered the region – is much better recorded, and has left an important cultural and natural legacy, in terms of toponymy, technology and heritage of the city.

The toponymy of the terms related to the mining world perfectly underlines the importance of this Arab-Muslim heritage. As we have already explained, the very term “almadén” has an Arabic origin meaning “the mine”, which has given the name to other, and several, mining towns such as Almadén de la Plata, Almadenejos or the Cerro de los Almadenes, in Otero de Herreros (Segovia). In Portugal there is also a town called Almada, while in the United States there is a valley and mines called New Almaden.

There are also other words of Arabic origin related to mining and metallurgy, such as aludel[3] (in Arabic ﺍﻟﻟﻮﺛﻞ), jabeca[4] or azogue[5]… It is also important to mention that it was during the Muslim era when the use of distillation boilers was developed to obtain mercury from the cinnabar extracted from the mine.[6].

The Arab-Islamic heritage and legacy of the mining world

It is important to know that in order to separate mercury from sulfur, it must be heated to over 210 degrees Celsius. This high temperature allows the decomposition of the SHg molecule, causing the mercury to go to a vapor state which, once cooled, becomes a liquid. Therefore, to produce mercury from cinnabar, a technology was needed to heat it, in other words, an oven.

Thus, before the period of Al-Andalus, it seems that the mine served only to extract cinnabar in order to produce vermilion. Despite this, there is no doubt that the latter knew the means to extract mercury from the ore, since in the books of Greek and Roman scholars we find different techniques to transform cinnabar into mercury. This is the case, for example, of the methods of Theophrastus, Dioscorides and Pliny[7].

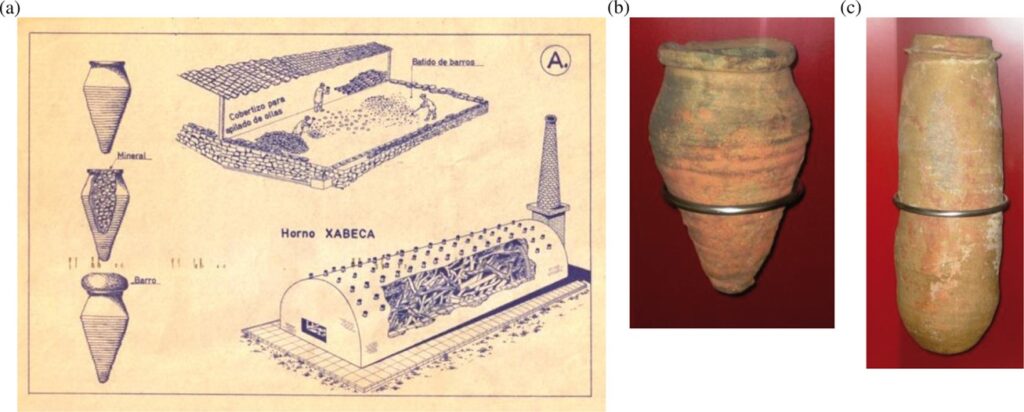

However, the first oven documented in Almaden were introduced by the Arab-Muslim populations, the famous xabecas oven. These ovens allowed the development of a new method for obtaining mercury, based on the great knowledge and teachings in alchemy of Muslim scholars such as Jabir ibn Hayyan (who discovered for example nitric acid).

As explained in an interesting research article published in 2014 in the Revista De Metalurgia, this oven:

“was composed of four vertical walls of rectangular plan, closed by a semicircular vault. In the vault there were several holes in a variable number of 18 to 24, depending on the case, whose appearance gave the shape of a net from which it took its name.

The process consisted of preparing the pots or xabecas (Fig. 1b) by filling them with mineral, which was previously crushed. Then, they were covered by means of covers or lids and finally placed in the holes of the kiln cover. Inside the oven, the firewood was placed to heat the pots and the cinnabar was introduced into them so that the mercury could volatilize. The quicksilver was deposited in the upper part of the pots. Once the oven had cooled, the covers were uncovered and the liquid mercury was obtained wrapped in ash and stones. Finally, the mixture was washed to separate the mercury.”

However, these ovens have not survived the passage of time and technological revolutions. Today, only a few xabeca pots remain, which can be visited in the Mining Park.

The colonization of America and the exploitation of its numerous gold mines caused an explosion in the demand for mercury and, therefore, the need for greater productivity in the manufacture of silver. Thus, the Arab xabecas ovens were replaced by reverberatory ovens, but above all by aludel ovens from 1646 onwards.[8] This is a oven whose creation is not linked to the Muslim period, but whose name continues to derive from the Arabic.

Bibliographic sources on the mining sector in Al-Andalus

In addition to the visible remains, there are also texts from the period that mention Almadén and its mine. This is for example the case of Ibn Hawqal with his Ṣūrat al-‘Arḍ, or the geographer, botanist and historian Abdallah al-Bakri, who mention the location of these mines.[9]

One of the most important and detailed descriptions of this mine is that of the famous geographer and traveler al-Idrisī, who mentions the production of mercury from Almadén and Obejo, stressing that it was exported to the entire Mediterranean basin.[10] He also stated that the Almadén mine had a depth of 250 fathoms, or 420 meters, making it the deepest mine in the world at this time.[11]

Ibn Ḥayyān also relates that ‘Abd al-Raḥmān III had a mercury basin installed in the main hall of the palace of Madīnat al-Zahrāʼ that produced reflections in the sun, and whose material probably came from the mines of Almadén.[12]

A history marked by slavery and forced labor

There are other sources that detail that around 1,000 laborers worked in the mine, in the extraction, transformation and production of mercury. As for the miners and workers, it is necessary to remember that, throughout time, and especially since the 16th century, the slave labor force in these mines has been very important.

First of all, it is important to know that until the middle of the 17th century, the mines were owned by private individuals by virtue of a right granted by the Crown of Castilla; however, from 1645 onwards, the management of the mine passed into the hands of the State.

In fact, a sentence was created that sent the condemned directly to work in the Almadén mines, which was associated with the galley slave. The desire to increase their production, yield and productivity led to the use of prisoners and slaves in this work process. With the increasing arrival of slaves, and the growing demand for mercury, several buildings were built in the 18th century, such as the Royal Hospital for Miners of San Rafael, the Bullring and, above all, the Royal Prison for Forced Laborers.

Thus, forced labor left its mark on the mine for a long time, both with prisoners, who according to mining records were thirty in 1566 and between sixty and eighty in 1623, and with slaves, with an equal or greater number.

The tasks of slaves and prisoners were especially dangerous. Among the sources detailing this grim period, Mateo Alemán stands out. The latter left us a “Secret Report” in which he speaks of forced labor in the mines, emphasizing the harsh working conditions in 1593.[13]

His research was prompted by rumors about the poor working conditions of the galley slaves.He conducted numerous interviews with mine workers, such as Marcos Hernández described as a native of the Berber Coast (a term used since the 16th century to refer to the coastal regions of Morocco, Algeria, Tunisia and Libya) and neighbor of Granada, whose conviction is explained because: “being enlisted as a neighbor of this town (Almadén) with the natives of the kingdom of Granada, he left his lodging and went to Seville.”[14] His work allows us to know that most of the forced laborers were mainly gypsies, Moors and bandits.[15]

UNESCO World Heritage Site

On June 29th, 2012, the Almaden Mining Park was added to the UNESCO World Heritage List. Nowadays, the Almadén mines can be visited, allowing us to travel back in time and discover a spectacular industrial archeology dating from different periods.

References

[1] Hirst, K. Kris. «Cinnabar, the Ancient Pigment of Mercury.» ThoughtCo, Aug. 25, 2020, https://www.thoughtco.com/cinnabar-the-ancient-pigment-of-mercury-170556

[2] A method to extract silver from ore, using salt and copper(II) sulfate in addition to mercur

[3] “Each of the baked clay pipes, resembling a bottomless pot, which, connected with others in a row, are used in the ovens of Almaden, Spain, to condense the mercurial vapors produced by the calcination of the quicksilver ore.” Real Academia Española (https://dle.rae.es/aludel). [Translation from Spanish to English by Tristan Semiond]

[4] “Distillation oven, formerly used in Almaden, Spain, which consisted of a rectangular factory with its tip and draft chimney, and covered by a barrel vault with several rows of holes, where the pots were placed almost full of quicksilver ore stirred with “hormigo.” Real Academia Española (https://dle.rae.es/jabeca?m=form) [Translation from Spanish to English by Tristan Semiond]

[5] It is a synonym for mercury and can be used as a reference to a ship that was used to transport quicksilver from Spain to America. According to the RAE it comes from the Hispanic Arabic. azzáwq, this from the classical Arabic zāwūq or zā’ūq, and this from the Pelvi zīwag.

[6] OCTAVIO RUCHE RIARl. “La minería visigótica y musulmana en la Península Ibérica”. BOCAMINA I Patrimonio minero de la Región de Murcia. p.90

[7] Tejero-Manzanares, J., Garrido Sáenz, I., Mata Cabrera, F., Rubio Mesas, M.L. (2014) “La metalurgia del mercurio en Almadén: desde los hornos de aludeles a los hornos Pacific”. Revista De Metalurgia, 50(4): e033. doi: http://dx.doi.org/10.3989/revmetalm.033

[8] Tejero-Manzanares, J., Garrido Sáenz, I., Mata Cabrera, F., Rubio Mesas, M.L. (2014) “La metalurgia del mercurio en Almadén: desde los hornos de aludeles a los hornos Pacific”. Rev. Metal. 50(4): e033. doi: http://dx.doi.org/10.3989/revmetalm.033

[9] http://histara.sorbonne.fr/cr.php?cr=375

[10] Juan Aurelio Pérez Macías.”La minería metálica en al-Ándalus” in ECONOMÍA Y TRABAJO LAS BASES MATERIALES DE LA VIDA EN AL-ANDALUS (dir. María Mercedes Delgado Pérez, Luis-Gethsemaní Pérez-Aguilar). Ediciones Alfar, 2019, pp.143-144.

[11] OCTAVIO RUCHE RIARl. “La minería visigótica y musulmana en la Península Ibérica”. BOCAMINA I Patrimonio minero de la Región de Murcia. p.90

[12] Juan Aurelio Pérez Macías.”La minería metálica en al-Ándalus” in ECONOMÍA Y TRABAJO LAS BASES MATERIALES DE LA VIDA EN AL-ANDALUS (dir. María Mercedes Delgado Pérez, Luis-Gethsemaní Pérez-Aguilar). Ediciones Alfar, 2019, pp.143-144.

[13] Mariano Calvo. “La bajada a los infiernos de Mateo Alemán, autor de Guzmán de Alfarache”, ABC, 29/01/2014. https://www.abc.es/toledo/ciudad/20140129/abci-bajada-infiernos-mateo-aleman-201401292058.html

[14] Ibid.

[15] Ibid.